New Lighter, Smaller and Faster Sparrow, DexForce intelligent 3D industrial camera, makes robotic arm guidance lighter

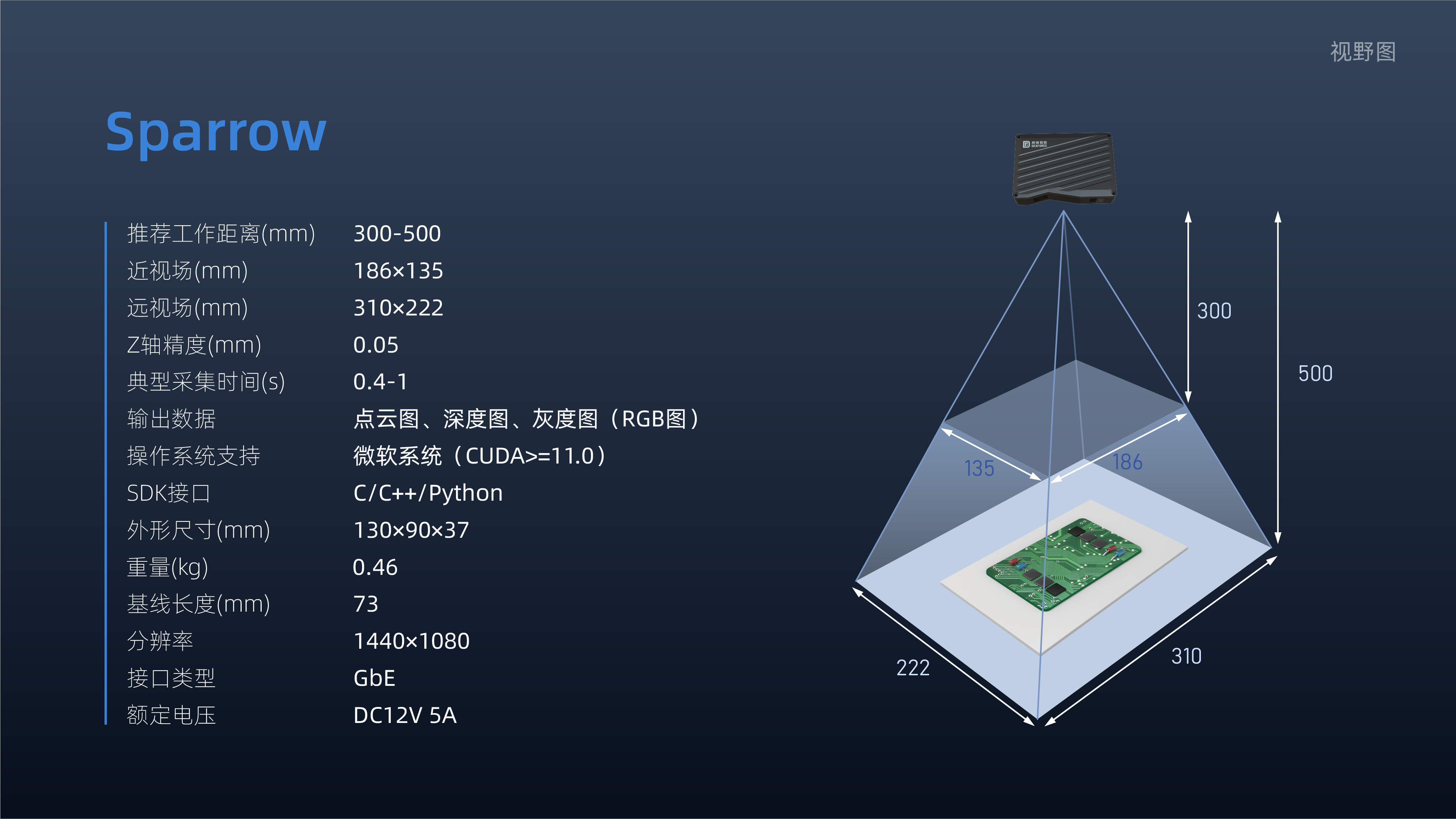

Recently, DexForce Intelligence released a new self-developed Sparrow series lightweight DLP monocular structured light camera series, which uses active structured light 3D reconstruction technology, with ultra-high precision, faster and finer imaging, mature and stable solution, excellent resistance to ambient light and other performance. And with its ultra-light weight of 0.46kg, it is ideal for the flexible and precise operation needs of modern industry.

Better Performance

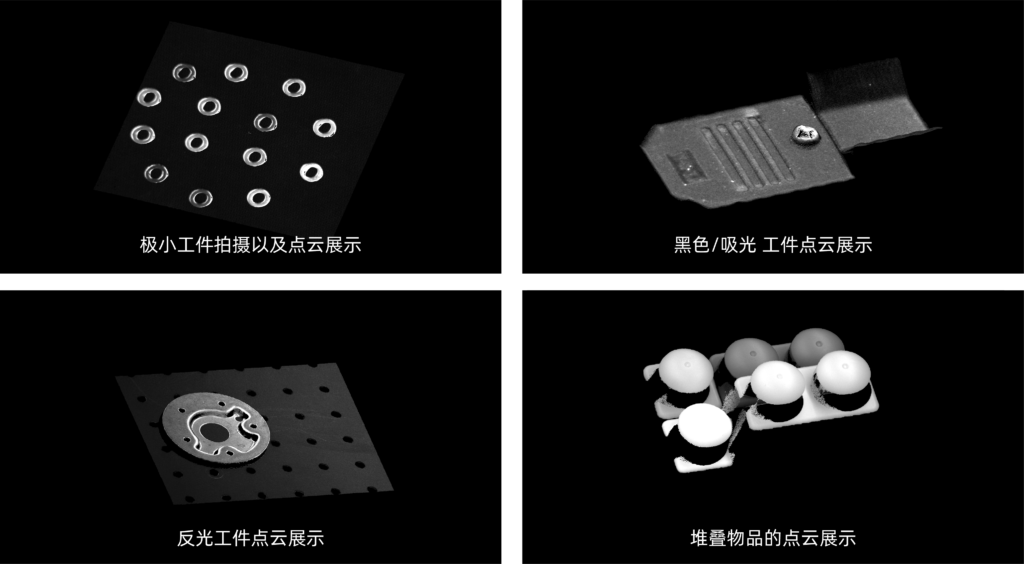

Excellent imaging effect, ultra-high precision image acquisition

The Z-axis accuracy of the new generation of Sparrow camera can reach 0.05mm, which can generate accurate, complete and detailed high-quality point cloud data for all kinds of typical workpieces in the size of mm/micron, and can effectively cope with the needs of dark/light absorption, a certain degree of reflection, structural precision and other complex conditions of image shooting. Suitable for small and medium-sized workpiece identification, positioning, high-precision measurement, etc.

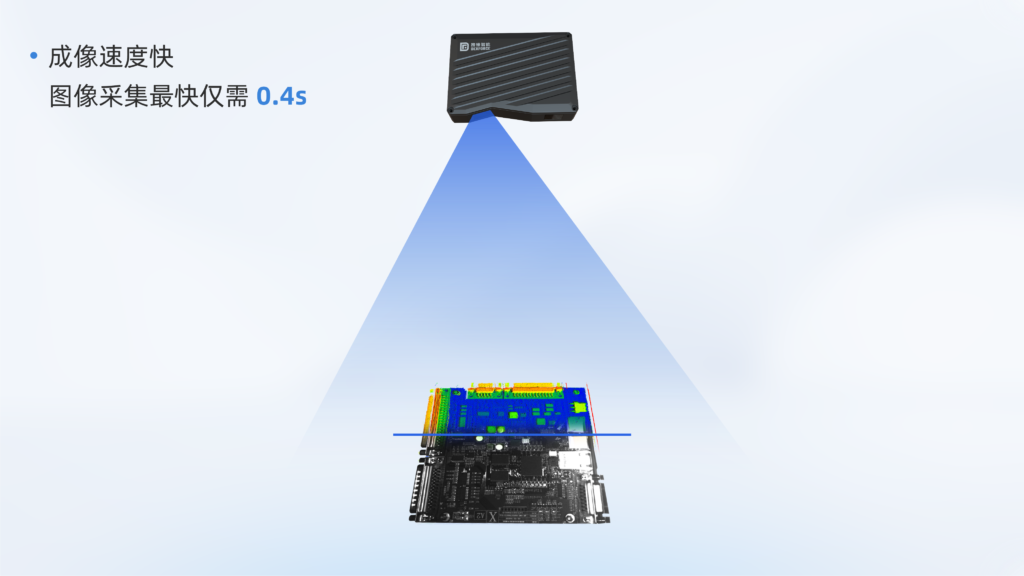

The imaging speed is fast, and the fastest image acquisition is only 0.4S

Sparrow series camera adopts self-developed high-speed structured light technology, from taking pictures to acquiring 3D data only takes 0.4S, meeting the actual requirements of typical application scenarios. For applications positioned in the “eye on hand”, the Sparrow series camera’s extremely fast imaging speed ensures the operation of the robot arm and provides real-time information adjustment operations, further improving production efficiency and reducing production site replacement costs.

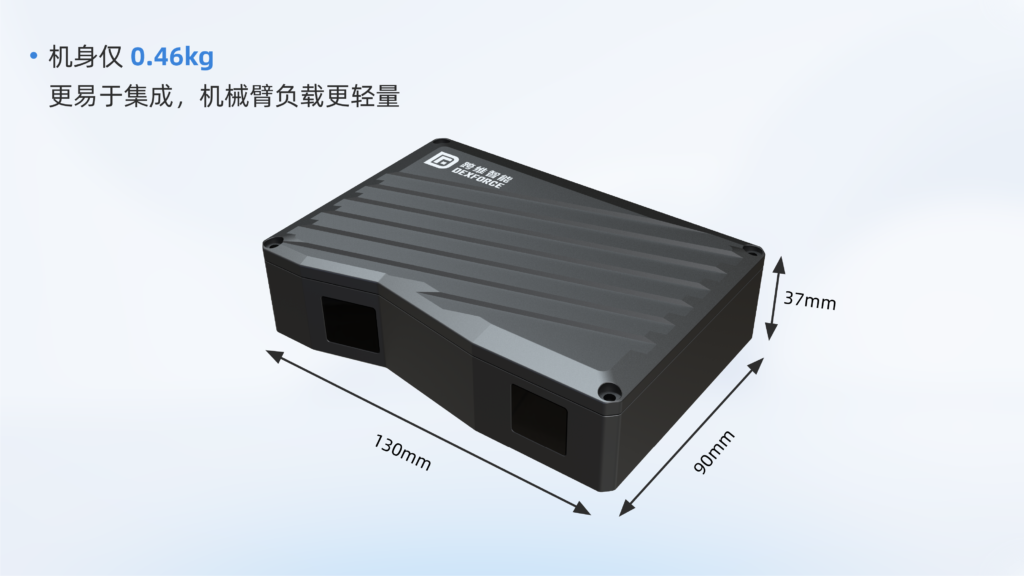

Easier integration and lighter arm load

Thanks to the Sparrow series camera’s further hardware structure optimization design, the product weighs only 0.46kg, the size is extremely small (only 130*90*37mm), and can be easily installed at the end of the robot arm (including collaborative robots, composite robots, etc.). Small and flexible, it can support fine operation scenarios such as positioning assembly and high-precision grasping in a narrower space. For arm loads, the lighter camera weight load at the end can further improve the installation and operation of the supporting vision system;

Easier deployment and support for multiple languages

Sparrow cameras are compatible with multiple SDK interfaces, which greatly improves development efficiency and flexibility. Support multiple language development, reduce the user’s learning cost, greatly reduce the difficulty of using the camera.

More cost-effective, the price is very competitive

The Sparrow D Series lightweight DLP monocular structured light camera series remains cost-effective while continuously optimizing the structure and further improving the performance. More convenient to use, easier to operate, the price is still very competitive.

Application scenario

As an “Eye-in-Hand” 3D industrial camera, the Sparrow series is not only smaller and faster, but also lighter to mount at the end of a robotic arm, but also more suitable for the needs of equipment integration in more small and precise Spaces. At present, it has been widely used in precision assembly, high-precision quality detection, workpiece identification and positioning, intelligent sorting, size detection, defect identification, volume measurement and other scenarios.

In the future, Dexforce intelligence will always take market customer demand as the starting point, and continue to create products that exceed customer expectations, with Sim2Real as the core technology, to create a soft and hard product matrix, to help enterprises improve production efficiency and reduce production costs.

At present, the first cameras for new products will give customers a very cost-effective experience price. For more information, please contact us by scanning code!